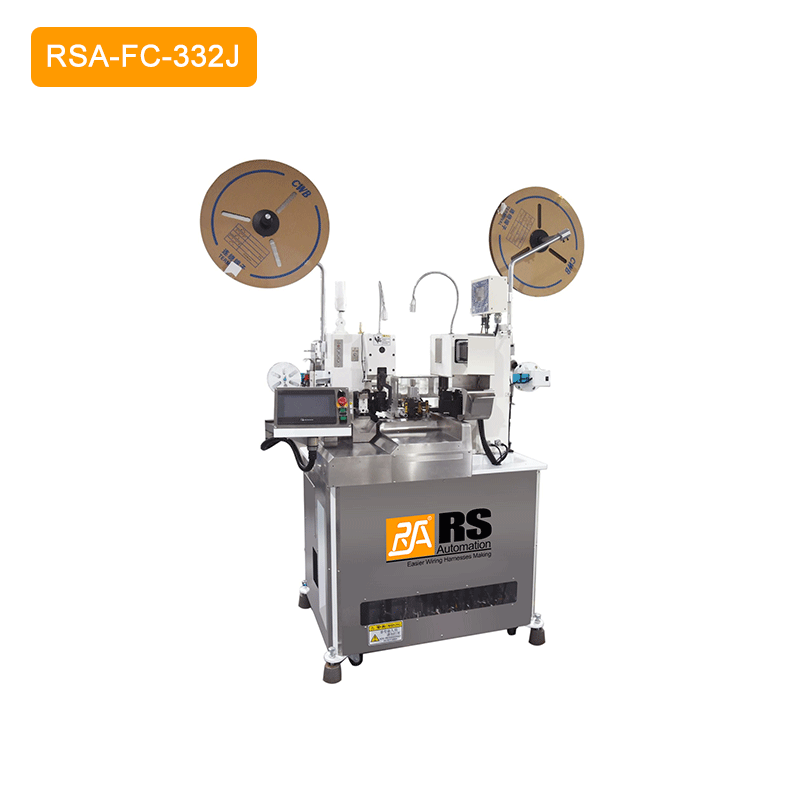

Feature

- High accuracy. Driven by Mitsubishi servo motor (8 servo motors total in the machine) and liquid bead screw, which guarantee accurate position of cable feeding, stripping and crimping.

- High processing efficiency with 3500-3600pcs per hour.

- Cost-saving. The automatic detection function can detect defective products immediately and improve product pass rate.User-friendly.

- Cutting length, stripping length, cut depth and crimping position are adjustable on HMI.Labor-saving. The machine can distinct Good & NG products and cut defective products.

- MES system is available, real-time uploading, making it easy to record and troubleshoot, with function of crimp tool service life recording and machine service life alarm.

- CFM/A is optional to provide alarm function for poor crimping such as over-crimping, insufficient crimping and copper damage.

- CCD visual detection is optional, which detects crimping effect, tape wrapping position, and wire seal insertion position.

.png)

-100x100.png)